HF START VS. LIFT START TIG VS. SCRATCH START

If you are left “scratching” your head about the differences in the different start methods of TIG, you are not alone. Many experienced users get the facts wrong when it comes to the 3 basic ways you can start a TIG arc.

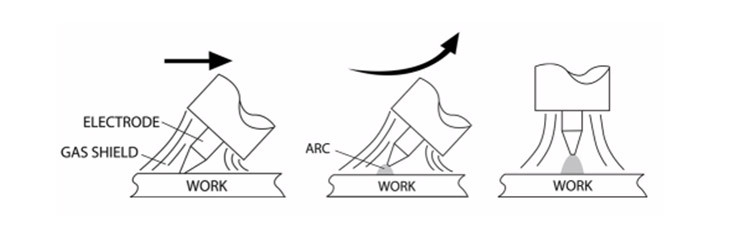

Scratch start TIG is probably the oldest method of starting an arc. It’s not a pretty process as it involves flicking near molten tungsten across the metal until an arc starts. The Scratch start method is similar to striking a match on a box. It works well, and it allows almost any DC stick welder to be turned into a TIG welder without much work. But Scratch start has some significant draw backs as the tungsten gets hot almost instantly as the arc is struck and small bits and pieces of the tungsten break off and get stuck in the weld. This can cause structural problems later. For general work though it works pretty well. Scratch startis a good way to get started TIG welding and is used throughout the world on a daily basis. It is far from falling out of use.

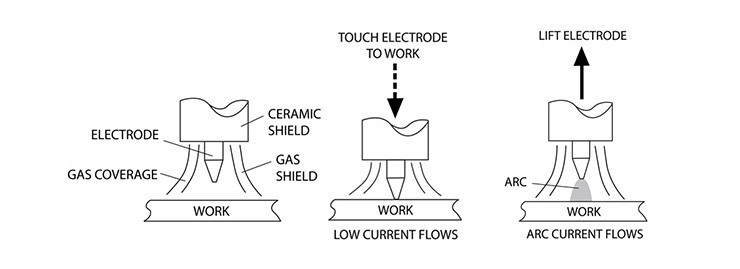

Lift start is probably the most misunderstood form of starting. A lot of times it is confused with scratch start. It may look similar but is far from it. It is a relatively clean process even though it involves contact with metal. The lift start involves bringing the tungsten down quickly and lightly into contact with the metal, and then a quick lift up to “draw” the arc. What happens with lift start is the OCV of the welder cuts back to a very low voltage output when the unit senses it has made continuity with the work piece. Once lifted the unit shifts to a higher output as the tungsten leaves the surface. This creates little contamination and preserves the point on the tungsten. It is still not 100% clean. The tungsten still can get contaminated. But lift start is a much better option than scratch starting, for steel and stainless. But it is not a good option for Aluminum because of the affinity aluminum and tungsten have for each other.

The most popular and best option is the use of High Frequency start that generates a high frequency arc that is capable of ionizing the air and bridging the gap between the tungsten point and the work piece. TheHigh Frequency start is a touch-less method and creates almost contamination unless the tungsten is over sharpened or the amperage is turned too high at the start. It is an excellent choice for welding aluminum, and really is the only acceptable choice. Unless you need to weld Aluminum, you don’t have to really haveHigh Frequency start, but it is nice to have to weld AC or DC if you have the option.