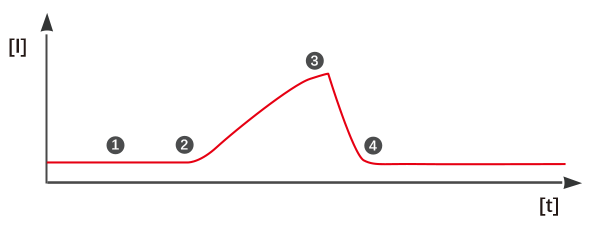

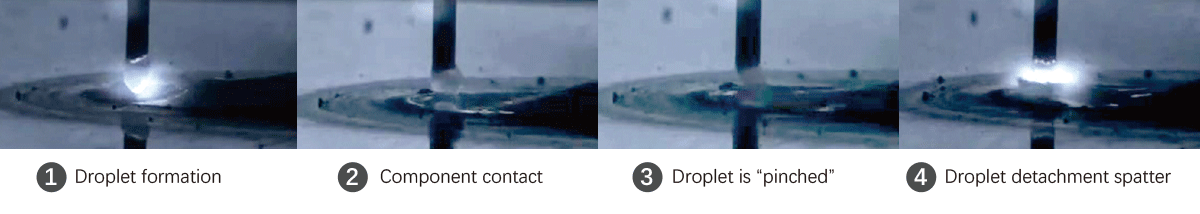

As soon as the short circuit is detected the current is increased. The arc ignites at a relatively high short circuit current and high arc pressure. This can lead to welding spatter and instabilities.

- The ULS process is a modified shourt-arc transfer arc, it controls the volatility during the change of state between short and arc to control the amount and size of the spatter generated.

- a) Standard Short Circuit Transfer Arc

- b) Standard-Short Arc

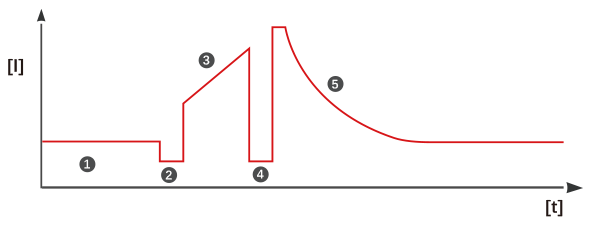

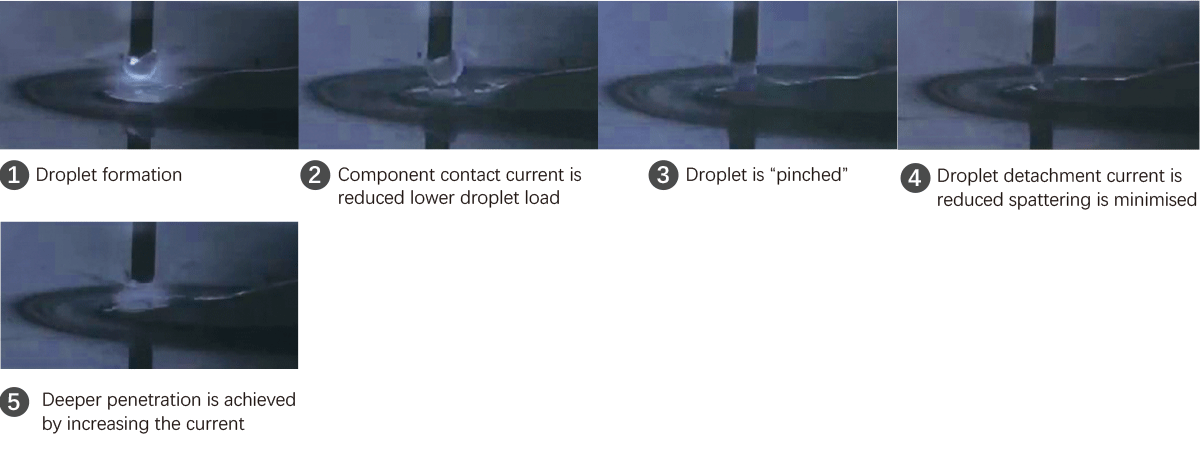

- c) ULS Transfer Arc

ULS ignites arc at relatively low current levels, relying on programmed to drastically reduce current during the pinch phase, thereby reducing the energy and spatter during droplet detachment and explosion. Also the gentle drop in current and the surface tension in the tail-out phase promotes a smooth and mild droplet transition, reducing CO2 impact and solid spatter.

- d) ULS-Short Arc

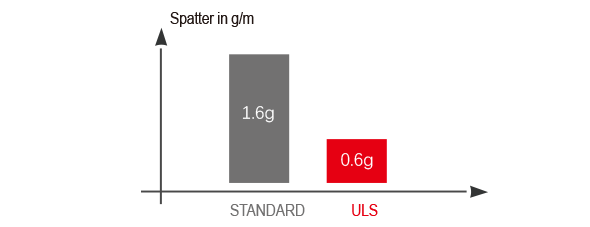

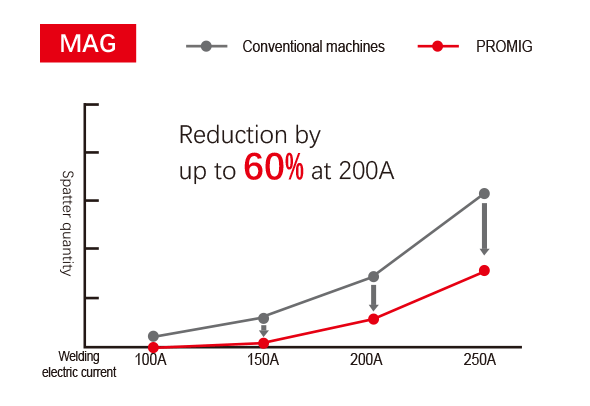

UP TO 75% LESS SPATTER

Spatter can be reduced by up to 75% even in high current ranges.

- • Less rework

- • Lower filler material consumption

- • Fewer rejects

- • Less cleaning required and savings on wearing parts

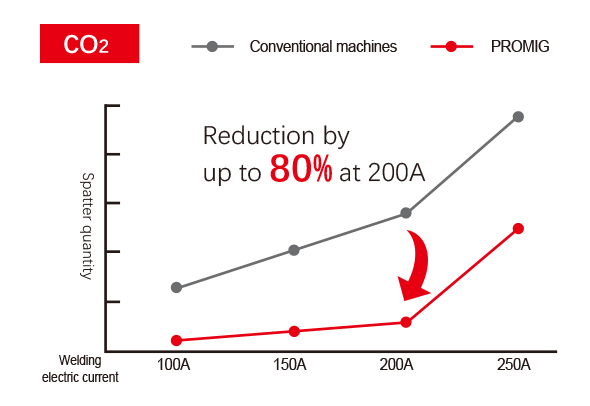

Up to 25% Savings on Gas Costs

- • Lower gas costs through the use of 100% CO2

- • Greater penetration through the use of 100% CO2

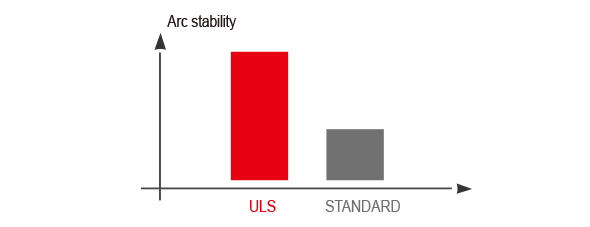

High Process Stability

- • Improved process stability in the area of the intermediate arc

- • No additional sensor line needed

High Process Stability

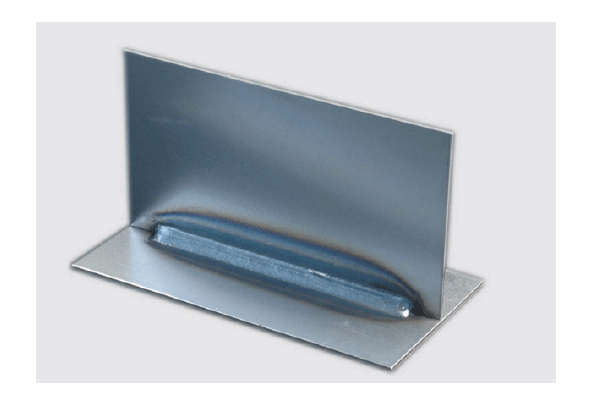

Extrmely Little Spatter

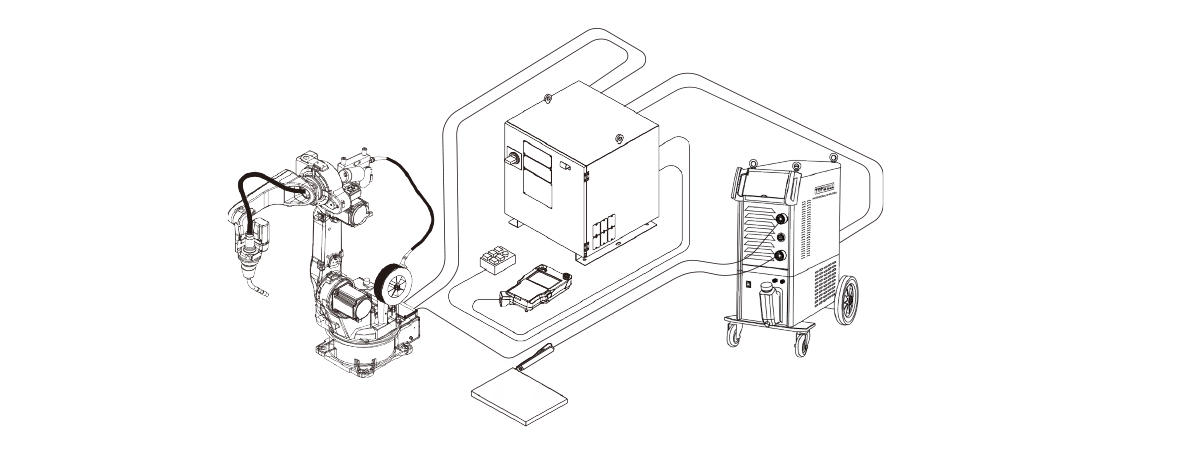

Welding with Robot or carriage to ensure an excellent performance.

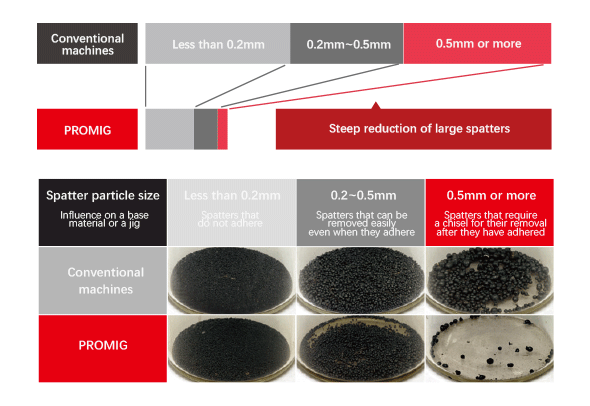

- Realization of low-spatter generation equivalent to MAG welding even using CO2 welding

- Reducing spatters to the utmost limit even by MAG welding

Furthermore, the adhesion of generated spatters to a base material or a jig can be reduced owing to the small particle forms.As a result, you can significantly reduce the number of man-hours required for removing spatters, leading to a reduction in the frequency of cleanup work of the nozzle.

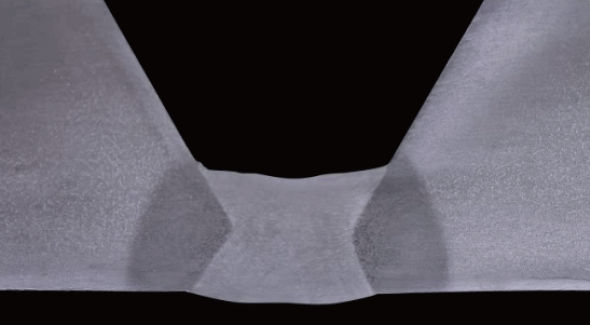

With challenging root passes where a higher arc pressure is required, the ULS Root characteristic impresses above all with its ease of use and perfect root formation.