MIG-250i/300i

/FEATURES

Quick Specs

- Light Industrial Application:

- Thin sheet metal fabrication

- Car repairs

- Agriculture

- Shipyards and offshore industry

- Installation and set-up

- Repair and maintenance

- Processes:

- MIG

- MIG (GMAW-P) Pulsed

- Stick (SMAW)

- Input Power:250P: 230V, 1-Phase

- 300P: 400V, 3-Phase

- Amperage Range:250P: 10-250A300P: 10-300A

- Rated Output at 40℃ (104℉):

- 250P: 250A at 26.5V @60% Duty Cycle

- 300P:300A at 29V @60% Duty Cycle

- Weight:32kg

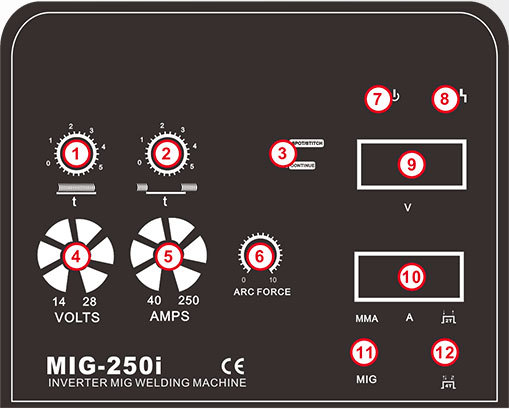

General View of Control Panel

1.Spot/Stick welding TIME 1:

on welding time adjustment knob.

2.Spot/Stick welding TIME 2:

off welding time adjustment knob.

3.Spot/stick welding mode selection knob.

4.Welding Voltage regulator.

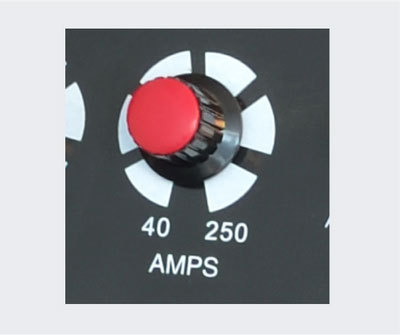

5.Welding Current regulator.

6.Arc Force regulator.

7.Power/working pilot lamp.

8.Arc Force regulator.

9.Over-load/Over-heat Protection

or Damage pilot lamp.

10.Volmeter.

11.MMA/MIG welding mode selection.

12.2T/4T selection.

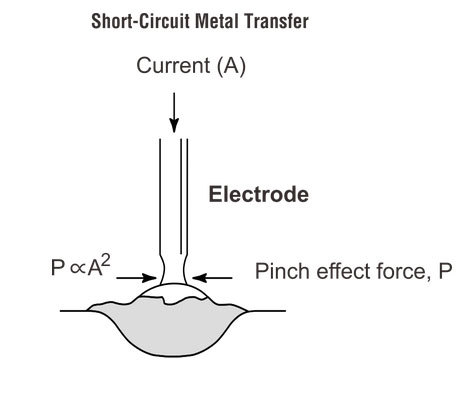

The short-circuiting metal transfer mode

The short-circuiting metal transfer mode is the low heat input

mode of metal transfer for GMAW and has higher electrode

efficiencies, 93% or more. The low heat input reduces

weldment distortion and makes it ideal for sheet metal

thickness materials.

Spot/Stitch mode

Use the spot and cycle arc timer you can easily

control the welding time and the stitch length during

the continue spot welding jobs.

Spot/Stitch mode provides a quick and effective

means for spot welding mild,galvanized or stainless

materials. Very useful for the car body repairs.Multipurpose AMP connectors

The 10 Pins multipurpose AMP connectors extend the usage range

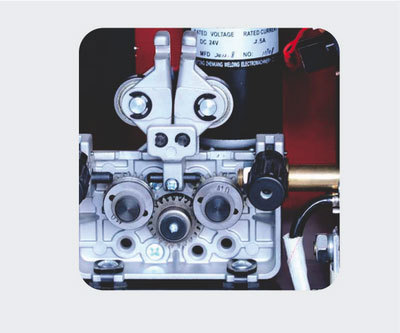

and it’s easy to work with a push-pull torch or spool gunand suitable a variety of filler wires.Four-Roll Drive System

4-Rolls wire-feeder with strong feeding motor.

Four-roll drive systems deliver the electrode to the welding torch.

It provides a stable wire speed and is popular for industrial applications./SPECIFICATIONS

Technical specifications

Item No MIG-250i MIG-300i Rated Input Voltage 1PH ~ 230V ±15% 3PH ~ 400V ±15% Max. Load Power Capacity 10.35KVA 12.04KVA Rated Duty Cycle(40℃) 60% MIG: 250A/26.5V MIG: Separated Wire-feeder: 300A/29V Internal Wire-feeder: 250A/26.5V MMA: 250A/28V MMA: 250A/28V 100% MIG: 200A/24V MIG: 200A/24V MMA: 200A/28V MMA:200A/28V Welding Current/Voltage Range MIG: 30A/15.5V~250A/26.5V MIG: 30A/15.5V~300A/29V MMA:30A/21.2V~250A/28V MMA:30A/21.2V~250A/28V Open Circuit Voltage 55V 55V Power Factor 0.8 0.8 Efficiency 80% 80% Pre-Gas Time Preset Preset Flow-Gas Time Preset Preset Wire-feed Mechanism 4 Rollers 4 Rollers Wire-feed Speed Range 0~25m/min 0~25m/min Wire Spool Capacity 300mm (15kg) 300mm (15kg) Filler Wires Ø (mm) Fe, Ss: 0.6~1.2 mm 0.6~1.6 mm Dimension (LxWxH) 770X250X650mm 770X250X650mm Weight (KG) 32 KG 32 KG

/ACCESSORIES

For Standard accessoriesFor Optional accessories/RESOURCES

/DOCUMENTS

- Mobile Phone

- *Title

- *Content

- Loading...