Home / All / Welding Equipment / All products / TOPWELL Inverter MIG 200 welding machine PROMIG-200SYN

TOPWELL Inverter MIG 200 welding machine PROMIG-200SYN

Synergic portable true pulse mig welder aluminum welding expert PROMIG-200SYN PULSE

Detail Information

DETAILS

Synergy, Portable, Pulse MIG

PROMIG-200SYN Pulse

Multi-Process Capable - Welds Flux-cored, Stick, Lift-TIG, Pulse MIG, advanced MIG for M.S/S.S.

Pulse MIG Process - Welds 4XXX and 5XXX series aluminum for superior quality welding.

Synergic Control - Set weld procedures with one control.

Built-in featured waveform - Provides a smooth, stable arc and superior, repeatable welds.

Dynamic Control - Controls the welding arc cone width from a softer arc to a harder arc.

True Pulse MIG For Aluminum

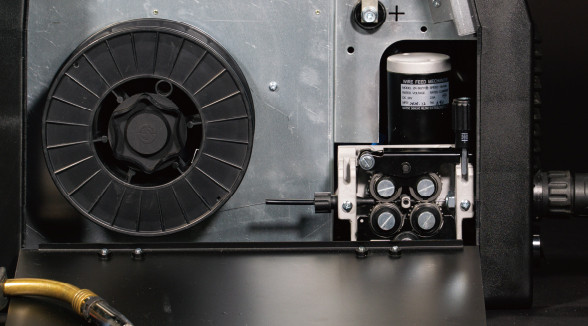

4-Roller wire-feeder

Four-Rollers drive system provides a steady and smooth wire feeding speed. It's a professional design and very important for welding aluminum.

HPC—Hybrid Pulse Control

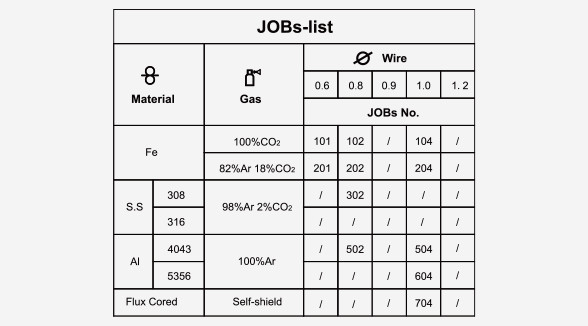

3 Steps To Start Perfect Welding

1. Regarding to the Job-List, set Job Number

| 2. Regarding to the base metal thickness,set welding current |

| 3. Go for welding! |

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

ProMIG-200SYN Pulse

|

|

Machines Processes

|

Stick (SMAW) Flux-Cored (FCAW) TIG (GTAW) MIG (GMAW) Pulsed MIG (GMAW-P) |

|

Wire Feeder

|

4-Rollers

|

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

490x230x385mm

|

|

Net Weight

|

20kg

|

Basic Specification

|

Input Voltage

|

1PH ~ 230V ±15%

|

|

Input Power

|

8.75KVA

|

|

Output Range

|

MIG: 10A/14.5V ~200A/24V TIG: 5A/10.2V~200A/18V MMA: 20A/20.8V~200A/28V |

|

Rated Output(40℃) 35%

|

MIG: 200A/24V TIG: 200A/18V MMA: 200A/28V |

Polarity | DC |

YOU MAY ALSO NEED

Related Products

ANY COMMENTS? YOU ARE WELCOME TO LEAVE MESSAGE TO US!

- Mobile Phone

- *Title

- *Content

Review

- Loading...