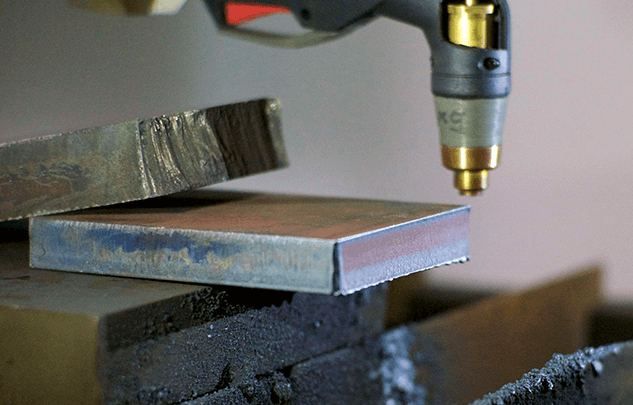

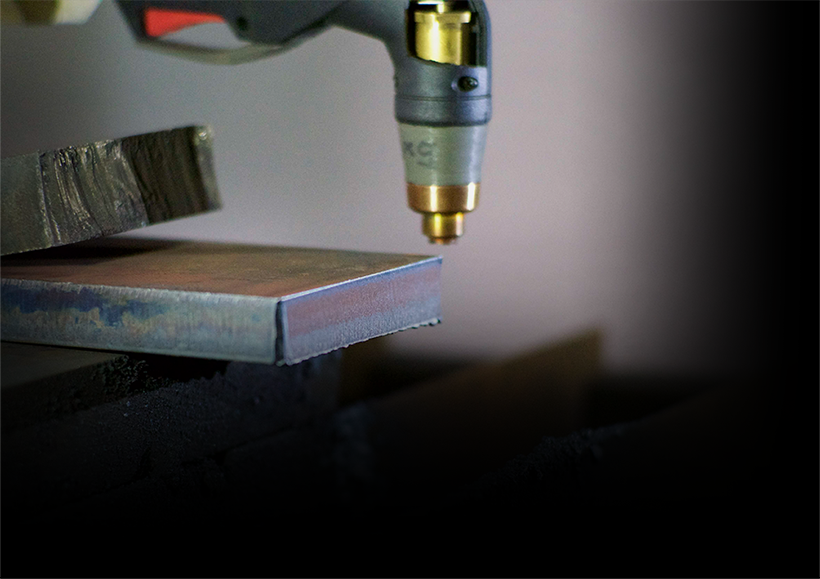

TOPWELL metal plasma cutter machinefor cutting 12mm thickness metal @500mm/min PROCUT-75MAX

-

PROCUT-75MAX

Classical, Reliable, Powerful, wildly used for Manual cutting, Gouging or even CNC cutting

-

Application:

Home workshop

Metal workshops

Light fabrication,

Repair and maintenance -

These Materials:

Mild Steel

Brass

Stainless Steel

Copper

Aluminum -

Input Power: 340-460V, 3-Phase

Amperage Range: 30-75A

Rated Output at 40℃ (104℉):

75A @60% Duty Cycle

Weight: 22KG

ADVANTAGES

-

- Light weight, compact design and convenient mounting feet allow for easy mounting in any application.

- Finish jobs faster with cut speeds two and three times greater than other traditional cutting process.

- Speed less time on secondary operations due to superior cut and gouge capacity.

-

- A powerful 60% duty cycle to handle long time production cutting in the toughest environments.

- The torch is versatile and durable enough to handle a variety of jobs.

- Topwell’s long-life consumable deliver operating cost that is less than half the competition.

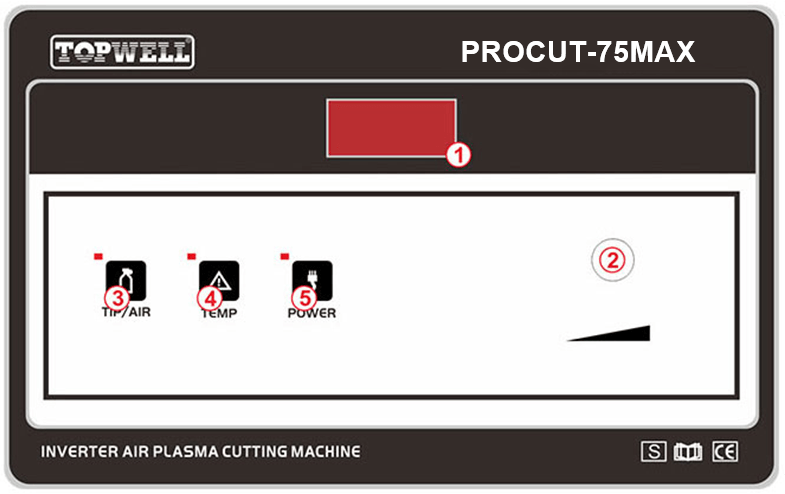

General View of Control Panel

1.Ammeter/Voltmeter Display

2.Encoder Control

3.Gas supply problem

4.Over heat/Over loading

5.Power LED

CUTTING CAPACITY

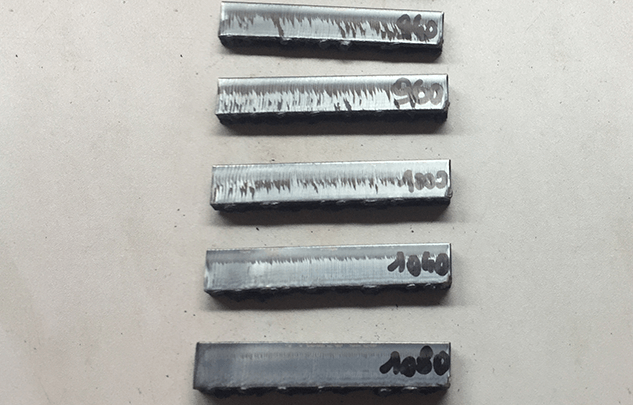

Capacity Thickness Cut speed Dross free(CNC) 12mm 900mm/min Pierce* 16mm (Use TP-105 Torch) Cut angle(ISO9013) Range 4 Recommended cut 25mm 500mm/min Severance(Hand cutting) 35mm 125mm/min *Pierce rating for handheld or with CNC torch height control

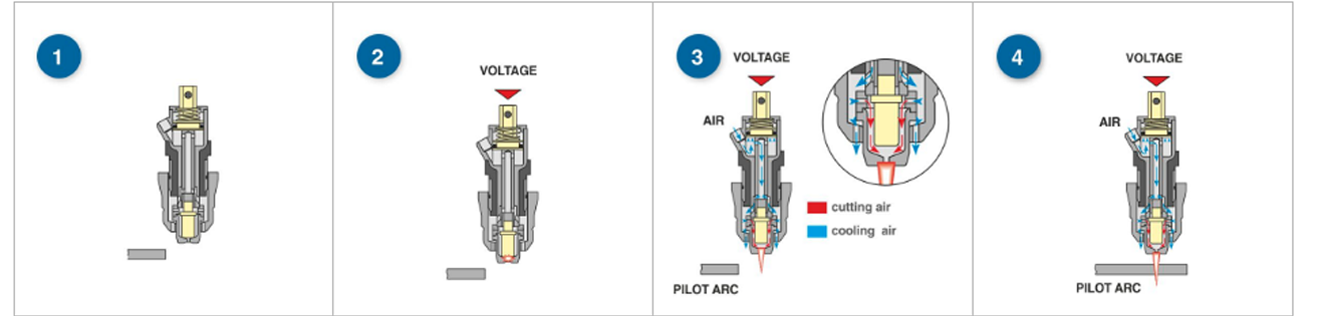

Non-HF Arc Ignition system

- Torch off.

- By pressing the trigger the torch will be fed by the current thus causing a temporary short circuit betweenelectrode and tip.

- The air then pushes up the small piston, thuscreating, between the electrode and the tip, the distance needed to strike the pilot arc.

- By positioning the torch on the part to be cut, theplasma arc will strike.

Torches with pilot arc cut in without high frequency.

Less electromagnetic disturbance, with consequent absence of problems for any electronic, radio, television, telephone and computer systems in the vicinity of the cutting positions.

Less electric stress on the torch - and on the respective connecting cables - due to the absence of the high voltage necessary for striking the arc Greater simplicity in comparson with other torches(without high frequency) on the market,with a consequent decrease of the risks of jamming in the mechanical pneumatic movement for striking the arc. Subject to wear (electrode, tips, nozzles, diffusers etc.), thanks to the better cooling of the torch obtained by reducing the insulating thicknesses (without endangering the safety parameters).

-

-

Item No PROCUT-75MAX Input voltages (±15%) 380V, 3PH, 50/60Hz

400V, 3PH, 50/60Hz

220V, 1PH, 50/60HzMax. Load Power Capacity 10KVA Rated output voltage 145VDC Max output current 75A Open circuit voltage (OCV) 300VDC Duty cycle rating 40°C(105°F) 380V/400V: 60% @75A

100% @60A

220V: 60% @75A

100% @ 60AOperating temperature -10℃~40℃ Dimensions 540x240x480mm Weight 22KG Torch PT80,6m

TP105,7.5mRecommended gas inlet flow rate/pressure CUTTING:400 scfh, 6,7 scfm @ 85 psi

Gouging:450 scfh, 7,5 scfm @ 70 psiCertifications CE, RoHS Warranty Power supply: 3-year

Torch: 1-year - ACCESSORIES

Handheld plasma torch: TP80 torch

CNC torch: TP105

Handheld gouging torch: TP120

Mechanical gouging torch: TP120

-

-

Q:Are you a factory or a trading company?

A: We are factory with more than 10 years manufacturing experience and we provide perfect OEM and after-sale service.

Q:How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments. For those orders less than 1000USD, we accept PayPal to pay.

Q:How about your warranty?

A: We offer 3-year product life guarantee ,and a generous 1 year warranty on al purchases that begins with the bill of lading.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price,please send the message on trade management or call us directly

- Mobile Phone

- *Title

- *Content

- Loading...