AC Waveshape Controls

AC Waveshape Controls

AC Frequency control

|  |

| Wider bead, good penetration ideal for buildup work | Narrower bead for fillet welds and automated applications |

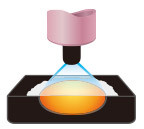

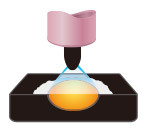

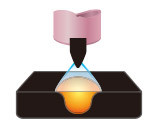

Controls the width of the arc cone. Increasing the AC Frequency provides a more focused arc with increased directional control.

Note: Decreasing the AC Frequency softens the arc and broadens the weld puddle for a wider weld bead.

AC Balance Control

|  |

| Wider bead, good penetration ideal for buildup work | Narrower bead, good penetration ideal for buildup work |

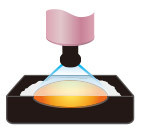

Controls arc cleaning action. Adjusting the % EN of the AC wave controls the width of the etching zone surrounding the weld.

Note: Set the AC Balance control for adequate arc cleaning action at the sides and in front of the weld puddle. AC Balance should be fine tuned according to how heavy or thick the oxides are.

Amplitude Control

|  |

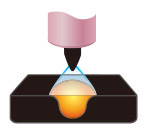

| More current in EP than EN: Shallower penetration | More current in EN than EP: Deeper penetration and faster travel speeds |

Adjusts the ratio of EN to EP amperage to precisely control heat input to the work and the electrode. EN amperage controls the level of penetration, while EP amperage dramatically effects the arc cleaning action along with the AC Balance control.