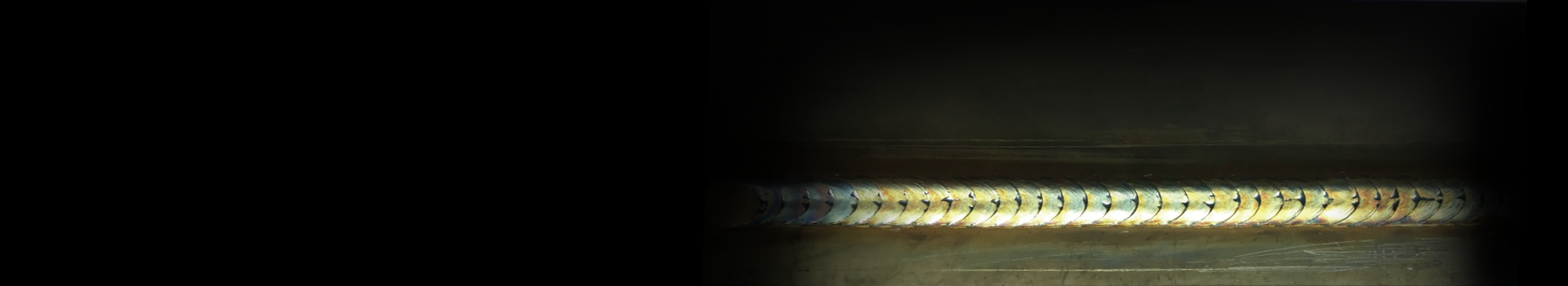

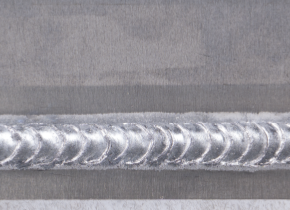

Get Beautiful Welding Seam

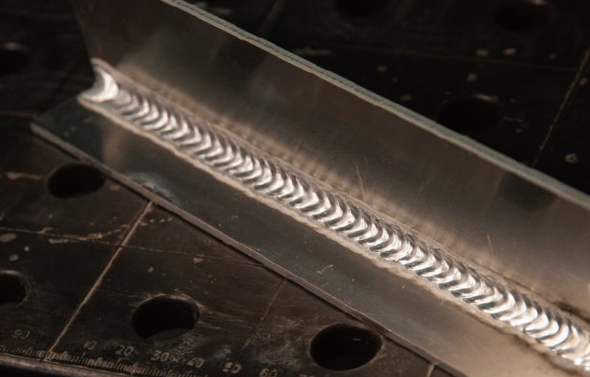

- Tig-like welding seam at mig/mag welding;

- better heat control in much lower distortion;

- low to no spatter.

- Tig-like welding seam at mig/mag welding;

- better heat control in much lower distortion;

- low to no spatter.

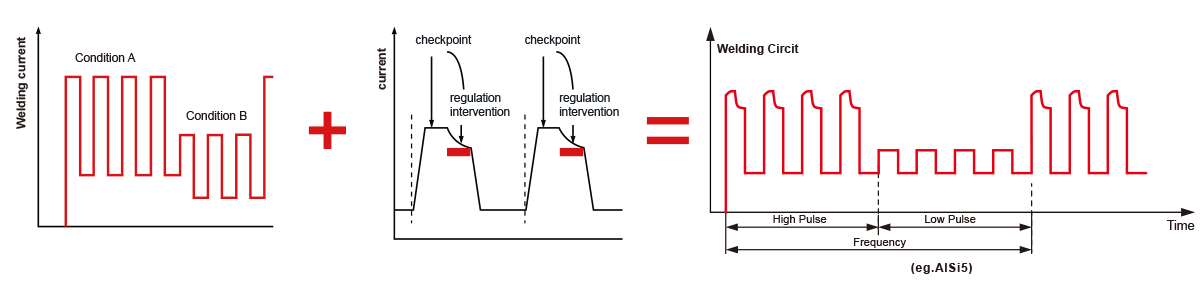

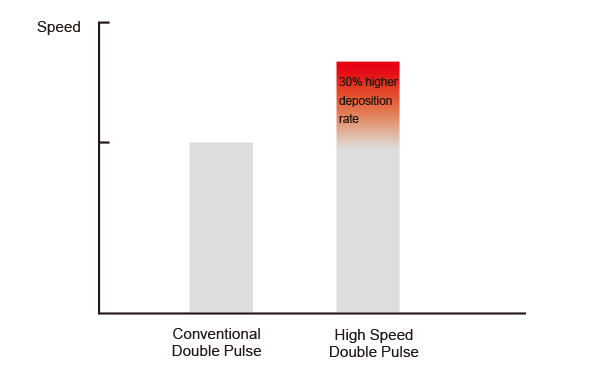

Controls the heating and cooling phases separately and specifically, HDP is particularly suitable for medium to thick-walled welding, especially for Aluminum and Steel applications.

Aluminum

Stainless Steel

Steel

Metal working

Structural fabrication

Boat, ship and yacht building