3 in 1 solar inverter Welder machine 200amp plasma Cutting STC-205Di

-

STC-205Di

3-IN-1 Multi-process: DC TIG + Plasma Cutting

-

Application:

Metal Fabrication

Maintenance and Repair

Auto Body

Light Industrial -

Processes:

DC TIG,

MMA(Stick),

Plasma cutting -

Input Power:

200-240V, 1-Phase

Rated Output at 40℃ (104℉):

TIG: 200A/18V/60%

PAC: 50A/100V/ 60%

MMA: 160A/26.4V/60%

Weight: 15kg

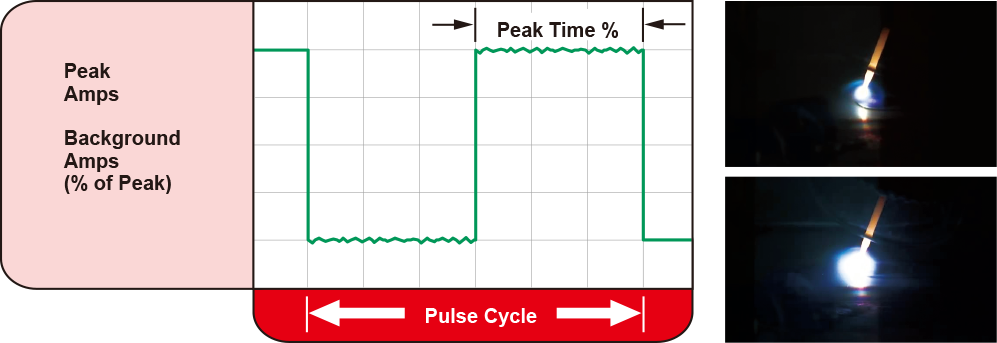

PULSED TIG

Conventional Pulsed TIG

Conventional Pulsed TIG

Typically from 0.2 to 10 PPS. Provides a heating and cooling effect on the weld puddle and can reduce distortion by lowering the average amperage. This heating and cooling effect also produces a distinct ripple pattern in the weld bead. The relationship between pulse frequency and travel speed determines the distance between the ripples. Slow pulsing can also be coordinated with filler metal addition and can increase overall control of the weld puddle.

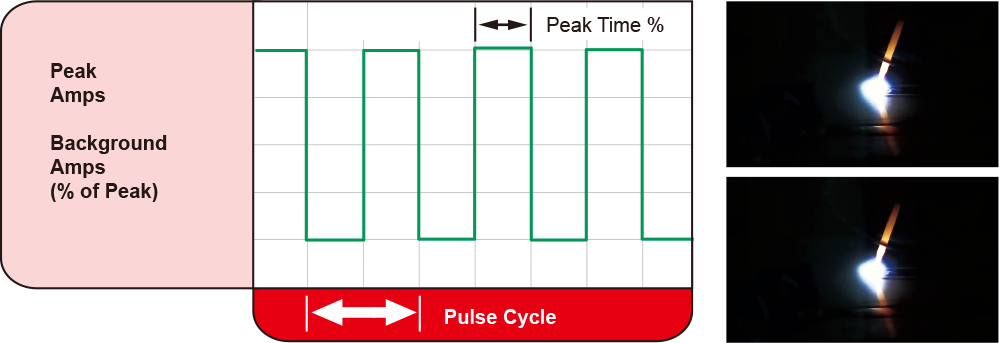

High Speed Pulsed TIG

High Speed Pulsed TIG

In excess of 40 PPS, Pulsed TIG becomes more audible than visible—causing increased puddle agitation for a better as-welded microstructure. Pulsing the weld current at high speeds — between a high Peak and a low Background amperage — can also constrict and focus the arc. This results in maximum arc stability, increased penetration and increased travel speeds.

CUTTING CAPACITY

Capacity Cutting Cut speed Recommended 10mm 500mm/min 15mm 250mm/min Severance(hand cutting) 18mm 125mm/min

-

-

Item No STC-205Di Rated Input Voltage 1PH ~ 230V ±15% Max. Load Power Capacity TIG: 5.63KVA MMA: 6.60KVA PAC: 8.20KVA Rated Duty Cycle(40℃) 60% TIG: 200A/18V MMA: 160A/26.4V PAC:50A/105V 100% TIG: 160A/16.4V MMA: 130A/25.2V PAC: 40A/100V Welding Current/Voltage Range TIG: 5A/10.2V~300A/22V MMA: 20A/20.8V~250A/30V PAC:20A/90A~50A/105V Open Circuit Voltage TIG/MMA:70V~80V PAC:260V~290V Power Factor 0.8 Efficiency 80% TIG Pulse Frequency 0.2Hz~200Hz TIG; Pulse Width (Ratio) 1~100% TIG; Arc-starting Current 5A~200A TIG; Crater-Filling Current 5A~200A TIG; Current Up-slope Time 0.1S~15S TIG; Current Down-slop Time 0.1S~15S TIG; Pre-Gas Time 0.1S~15S TIG; Flow-Gas Time 0.1S~15S TIG; Spot Arc Time 0.1S~10S MMA Arc Force 10A~160A MMA Hot Start Time 10A~160A MMA Hot Start Current 0.1S~3S PAC Required Air Pressure 0.3~0.5MPa PAC Gas Pro-flow/Retard Time 0.1S~15S PAC Quality Cutting Thickness(500mm/min) 12mm PAC Severance Cutting Thickness(125mm/min) 22mm Dimension (LxWxH) 410x190x305mm Weight 15KG Water-cooling Unit: WC-150 Operating Voltage 230V 50/60Hz Rated Power 260W Cooling Power 1.5KW(1L/MIN) Maximum Pressure 0.3MPA/60HZ Recommended Cooling Liquid 20%~40% ethanol/water Tank Volume 6.5L - For Standard accessories

TIG torch:TIG-26

Plasma torch: HT-50CB

Current: 50 Amp, Ignition: HF

Electrode holder with cable 2M

Earth clamp with cable 2MFor Optional accessories

BINZEL ABITIG ® GRIP 26

Argon gas regular

Trolley:WT-100

Foot Pedal

Plasma torch: Trafimet S25

Current: 25 A,

Ignition: Without HF

Water-cooling unit: WC-100

-

-

Q:Are you a factory or a trading company?

A: We are factory with more than 10 years manufacturing experience and we provide perfect OEM and after-sale service.

Q:How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments. For those orders less than 1000USD, we accept PayPal to pay.

Q:How about your warranty?

A: We offer 3-year product life guarantee ,and a generous 1 year warranty on al purchases that begins with the bill of lading.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price,please send the message on trade management or call us directly

- Mobile Phone

- *Title

- *Content

- Loading...