Home / All / Welding Equipment / MIG Welders / Topwell ULS350: Advanced Spatter-Free Thin Plate Welding Solution

Topwell ULS350: Advanced Spatter-Free Thin Plate Welding Solution

Topwell's ULS350 is a spatter-free welding solution for carbon steel up to 3mm, ideal for efficient robotic production in cycling and furniture.

Detail Information

DETAILS

ULS350

Designed for Thin Plate Within 3mm

Quick Specs

|

Item No

|

350 |

|

Input Voltage

|

3PH ~ 400V ±15% |

|

Rated Output(40℃) 60% |

350A/31.5V |

Cooling system | Air-cooled

|

Equipment

|

Welding process package

|

|

|

Short Arc (refined dip transfer)

|

●

|

ULS (ultra low spatter)

| ●

|

● Standard ○ Optional

Ultra Low Spatter Technology

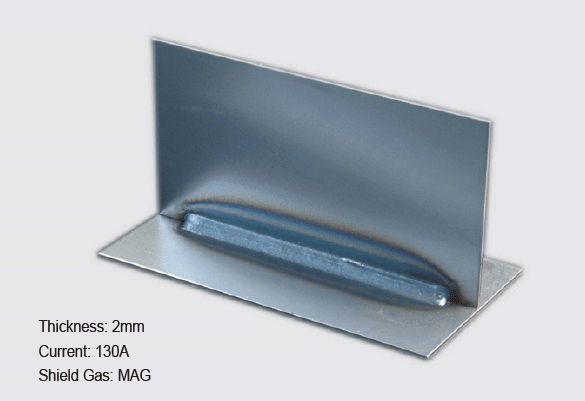

The ULS350 by Topwell is a specialized spatter-free thin plate welding solution, engineered to deliver superior welding results with ultra low spatter, minimal distortion and deep penetration. Designed for carbon steel up to 3mm thick, it excels in short-circuit transfer welding with even by CO2 shield gas, making it ideal for high-efficiency production in bicycle and furniture manufacturing industry by robotic welding.

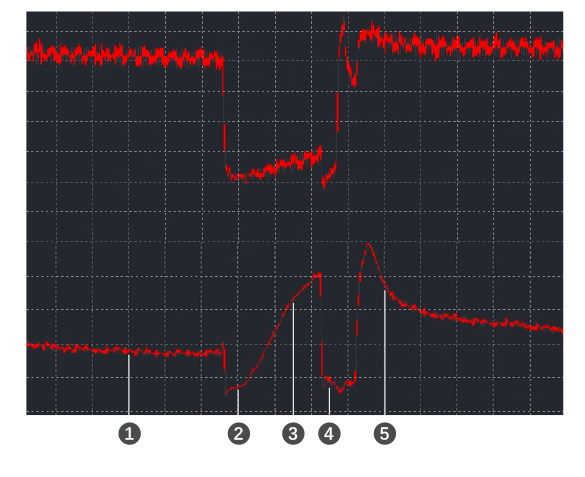

• How Ultra Low Spatter Technology Works

Topwell’s ULS technology optimized standard short-circuit transfer in five key phases:

1. Droplet Formation: A uniform droplet are produced at relatively low initial current level.

2. Droplet Contact: Reduce the current when the droplet touches the weld pool to minimize the contact spatter.

3. Pinch Phase: Keep increasing the current until the droplet are pinched to the greatest extent.

4. Droplet Detachment: Precise energy cutoff prevents spatter, enabling smooth transfer by surface tension.

5. Arc Re-ignition: Re-ignite arc at low current level and quickly increase the current for deeper penetration and smoother transfer. Readjust the current gradually back to low level for the next transfer.

• Benefits and Advantages

• Reduced Spatter & Waste – Up to 75% less spatter, minimizing rework and rejects for cleaner, more efficient welding.

• Minimal Heat Distortion – Precise heat input prevents warping, even on thin plates, ensuring better structural integrity.

• Consistent Deep Penetration – Stable arc length delivers deep, uniform penetration for stronger, high-quality welds.

• Faster Speeds, Superior Results – High process stability maintains exceptional weld ality at increased travel speeds.

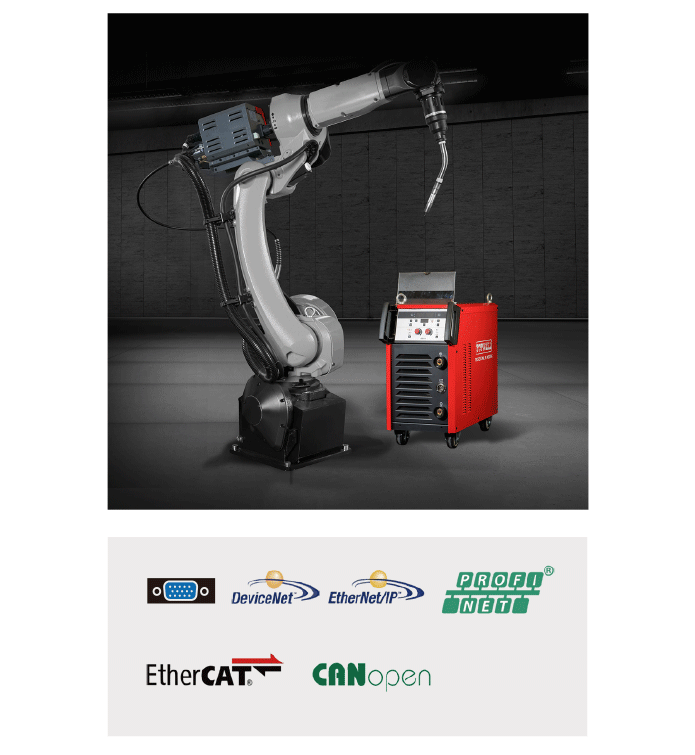

Idea for Robotic Welding

• The ULS350 achieves optimal efficiency and productivity when integrated with robotic systems, ideal for industrial applications.

• The automated system prevents instability caused by external factors, enabling ULS technology to perform at its full potential.

• Robotic welding significantly cuts costs by reducing labor, minimizing rework, and decreasing material waste.

• High quality welds with minimal defect and superior mechanical property are ensured by robotic welding.

• Robot interfaces are inserted via digital port (EtherNetlP, DeviceNet, CAN, CANOPEN, RJ485, etc.) with built-in communication protocols.

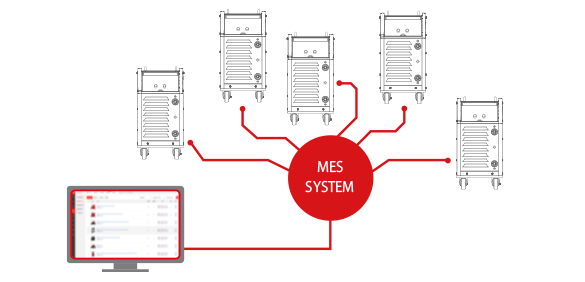

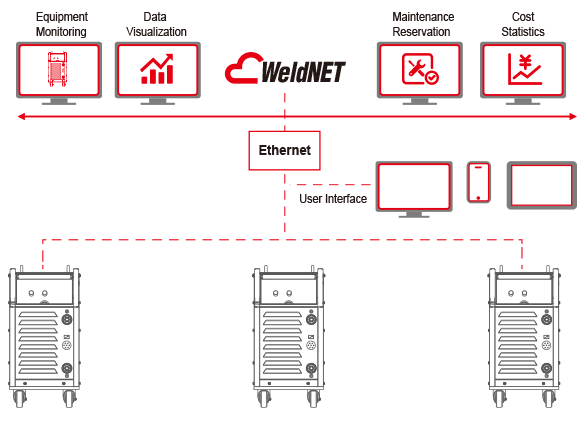

WeldNET and MES Accessible

ULS350 is equipped with active user management and assigned NFC keys to set protection and permissions for parameter adjustment. It can connect to the MES system, which is more suitable for modern production data management.

By connecting to Topwell WeldNET, you can pre-control the parameters, monitoring the process at real time, and trace the quality, thanks to the equipment, production, and process management modules. Meanwhile, your productivity and quality are boosted with analytic and statistical tools. It unleashes the potential of your future welding production.

SPECIFICATIONS

|

Product Name

|

ULS350 |

|

Mains voltage(V) |

3PH~400V±15%(50/60Hz) |

|

Max.Load Power Capacity |

18.1KVA |

Output Range | MIG: 30A/15.5V~350A/31.5V |

Rated Duty cycle at 40℃ (105℉): 60% | MIG: 350A/31.5V |

100% | MIG: 250A/26.5V |

Open Circuit Voltage | 70V~80V |

Power Factor | 0.87 |

Efficiency | 89% |

Wire feed unit | 4 rollers |

Wire feed speed range | 0~25m/min |

Wire SpoolCapacity | 300mm(15~20kg) |

Wires φ (mm): Fe | 0.8~1.2mm |

Flux-cored | 1.0~1.2mm |

Dimension (L x W x H): Machine | 655 x 300 x 620 mm |

Net Weight : Machine | 45kg |

YOU MAY ALSO NEED

ANY COMMENTS? YOU ARE WELCOME TO LEAVE MESSAGE TO US!

- Phone

- *Title

- *Content

Review

- Loading...